Screening for the raw material industry is the focus for our program. We supply equipment to screen materials from limestone and granite to coal to and diamonds, but also sands of all kinds.

Our wide product range includes hopper discharge feeder. Particularly noteworthy is the EXTROVIB ® system for the energy efficient emptying from hoppers.

We also manufacture equipment to handle all varieties of rocks and minerals utilizing rock feeder and conveyor tubes using both unbalanced and electromagnetic technology.

Electromagnetic Vibrating Feeder

Unbalanced Motor Vibrating Feeder

Exciter Driven Vibrating Feeder

Vibrating Feeders are either driven by Electromagnetic Vibrating Drives, Unbalance Vibrator Motors or Unbalance Exciter Drives. The Electromagnetic Vibrating feeders are used for precise feeding and the Unbalance Motors and Unbalance Exciter Driven Vibrating feeders are used for discharge of Bulk material at fixed feed rates. Compared to other conveying means, Vibratory feeders are low in energy consumption.

Vibratory feeders are available in open trough and tubular construction as per application requirement.

Some of the Industries that use these Vibrating feeders are Pharmaceuticals, Automation, Food Processing, Packaging, Glass Industry, Foundry, Steel, Construction, Recycling, Paper and Pulp etc.

ELEKTROMAG DEVICES PVT LTD.,

604, A2B, GOLDEN TOWER, AMLIDIH,

RAIPUR – 492006

TEL : 8085601869

EMAIL : raipur@elektromag.com

DIAMOND CHAMBERS, BLOCK -1 UNIT 10′ ‘0’ 10TH FLOOR ,

4 CHOWRINGHEE LANE,

KOLKATA -700 016

TEL : 033-40019355

FAX : 033-40019344

EMAIL : kolkata@elektromag.com

507, COMMERCE HOUSE,

9/1, CUNNIGHAM ROAD

BANGALORE -560 052

TEL : 080-41131838/22202041

FAX : 080- 22200119

EMAIL : bangalore@elektromag.com

E-13,BHOSARI , MIDC, GENERAL BLOCK ,

PUNE 411 206

TEL : 020-27122989/27111139

FAX : 020-27122332

EMAIL : pune@elektromag.com

303, DEVNARAYAN APARTMENTS,

2nd FLOOR ,60 RAMESWARAM ROAD T.NAGAR,

CHENNAI -600 017

TEL : 044-24315595

FAX : 044-24342855

EMAIL : chennai@elektromag.com

509, Wave Silver Tower, Opposite Atta Market,

Sector -18, Noida – 201301 (U.P.)

TEL : 011- 25746338

FAX : 011-25766364

EMAIL : newdelhi@elektromag.com

Light Machine Shop (Vapi) has CNC Lathes, VMCs, HMCs, Grinding Machine and Key Slotting Machine.

Light Machine Shop (Vapi) has CNC Lathes, VMCs, HMCs, Grinding Machine and Key Slotting Machine. EJV has a Heavy Duty Lathe (400 mm swing diameter x 2500 mm long) along with 2 machines have been bought from Germany (a) TOS Horizontal Boring Machine with Spindle diameter 130 mm and (b) Scharmann make Horizontal Boring Machine 90 mm Spindle diameter.

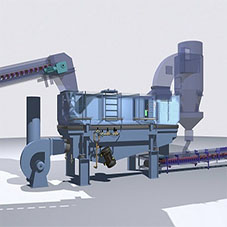

EJV has a Heavy Duty Lathe (400 mm swing diameter x 2500 mm long) along with 2 machines have been bought from Germany (a) TOS Horizontal Boring Machine with Spindle diameter 130 mm and (b) Scharmann make Horizontal Boring Machine 90 mm Spindle diameter. Sand attrition units type ZUFS are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler. Powerful, linear vibrations are disintegrating the lumps in the attrition sink and repulverize them to sand. Following the attrition sink the oversize grains are screened out with an easy to maintain mounted, well accessible and visible fine screen.

Sand attrition units type ZUFS are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler. Powerful, linear vibrations are disintegrating the lumps in the attrition sink and repulverize them to sand. Following the attrition sink the oversize grains are screened out with an easy to maintain mounted, well accessible and visible fine screen. The ZUFB machines are pre-reclaiming sand attrition units (Vibro V-jaw crusher) for big lumps of chemical bonded moulding and core sand. They are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable. The result: Small sand lumps, ready for further attrition. Note: A friction-based reclaiming unit model ZUFS needs to be installed after a ZUFB sand attrition unit. If high quantities of metal are embedded in the processed sand lumps, it is necessary to remove them before they enter the device.

The ZUFB machines are pre-reclaiming sand attrition units (Vibro V-jaw crusher) for big lumps of chemical bonded moulding and core sand. They are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable. The result: Small sand lumps, ready for further attrition. Note: A friction-based reclaiming unit model ZUFS needs to be installed after a ZUFB sand attrition unit. If high quantities of metal are embedded in the processed sand lumps, it is necessary to remove them before they enter the device. Furan sand reclamation plants for cold resin bonded sand. The available perfomance is from 1 t/h up to 20 t/h in single line applications. The available screen deck size range is up to 4500 x 4500 mm / 50 ton deck load in single deck applications.

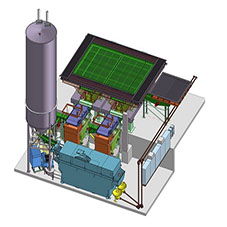

Furan sand reclamation plants for cold resin bonded sand. The available perfomance is from 1 t/h up to 20 t/h in single line applications. The available screen deck size range is up to 4500 x 4500 mm / 50 ton deck load in single deck applications.

Vibrating tables are used to compact various bulk materials, i.e. cold resin bonded moulding sand in nobake mouldlines. Jöst supplies vibrating tables combined with suitable roller track sections; this combo can be placed directly underneath the whirl mixer swivel range.

Vibrating tables are used to compact various bulk materials, i.e. cold resin bonded moulding sand in nobake mouldlines. Jöst supplies vibrating tables combined with suitable roller track sections; this combo can be placed directly underneath the whirl mixer swivel range.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The fluid bed cooler cools down the moulding sand which is conveyed from a crusher through an upstream magnetic drum into the cooler. The machine is not vibrating but stationary. The sand is fluidised by means of a special fluidisation plate by a powerful vertical air flow. It then has flow characteristics like water. When fluidised, the heat is released via contact heat exchange to a tube matrix with high surface passed by water.

The fluid bed cooler cools down the moulding sand which is conveyed from a crusher through an upstream magnetic drum into the cooler. The machine is not vibrating but stationary. The sand is fluidised by means of a special fluidisation plate by a powerful vertical air flow. It then has flow characteristics like water. When fluidised, the heat is released via contact heat exchange to a tube matrix with high surface passed by water.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

Sand attrition units are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler.

Sand attrition units are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler.

The pre-reclaiming sand attrition units for big lumps of organic bonded moulding and core sand are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable.

The pre-reclaiming sand attrition units for big lumps of organic bonded moulding and core sand are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable.

Shakeout screens are machines which are equipped with a heavy duty deck. The vibration features high acceleration and is directed vertically. This enables the machine to shake out nobake sand moulds.

Shakeout screens are machines which are equipped with a heavy duty deck. The vibration features high acceleration and is directed vertically. This enables the machine to shake out nobake sand moulds.

Used sand coolers serve for the cooling of hot foundry sand. The sand cooler consists of a vibrating conveyor made with an air-permeable bottom, a stationary exhaust hood, a moisturizing unit, a fan and a control unit. The sand is cooled under optimum heat transfer conditions in the fluidised bed by evaporation of water. The final moisture level is adjusted by the precisely controlled addition of water according to the temperature and throughput.

Used sand coolers serve for the cooling of hot foundry sand. The sand cooler consists of a vibrating conveyor made with an air-permeable bottom, a stationary exhaust hood, a moisturizing unit, a fan and a control unit. The sand is cooled under optimum heat transfer conditions in the fluidised bed by evaporation of water. The final moisture level is adjusted by the precisely controlled addition of water according to the temperature and throughput.

Gate feeders, which are especially suitable for the cast iron transport, are basically consisting of the vibrating trough, the trough carrying frame and the modular executed and standardised vibration absorber stations. The flexibility of the design allows a large distance between the absorber stations.

Gate feeders, which are especially suitable for the cast iron transport, are basically consisting of the vibrating trough, the trough carrying frame and the modular executed and standardised vibration absorber stations. The flexibility of the design allows a large distance between the absorber stations.

Sand conveyors are used below shakeout machines to convey the used sand over long distances in direction to the place where the sand is treated.

Sand conveyors are used below shakeout machines to convey the used sand over long distances in direction to the place where the sand is treated.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Due to vibration parameters, selected accordingly, the castings on a helical casting cooler are conveyed downwards. The cooling is effected by means of a convection heat exchange in counter flow.

Due to vibration parameters, selected accordingly, the castings on a helical casting cooler are conveyed downwards. The cooling is effected by means of a convection heat exchange in counter flow.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

Vibration shakeout drums are used, when the castings which have to be unpacked, are small and have few fins on the outside. When unpacking the castings, they will slightly collide with each other due to vibrations. Shakeout drums are mainly installed after vertically divided flaskless mouldlines.

Vibration shakeout drums are used, when the castings which have to be unpacked, are small and have few fins on the outside. When unpacking the castings, they will slightly collide with each other due to vibrations. Shakeout drums are mainly installed after vertically divided flaskless mouldlines.

The shakeout machines are equipped with an electronically adjustable angle of attack. Typically they are installed directly after a green sand mouldline. These proved machines are in a high quantity in practical operation in noted foundries. In general the machines are in use when sensitive cast parts needs to be unpacked.

The shakeout machines are equipped with an electronically adjustable angle of attack. Typically they are installed directly after a green sand mouldline. These proved machines are in a high quantity in practical operation in noted foundries. In general the machines are in use when sensitive cast parts needs to be unpacked.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

The spiral conveyor is a special type of vibratory conveyor that lifts product vertically. The product moves up the spiral as the conveyor vibrates.

The spiral conveyor is a special type of vibratory conveyor that lifts product vertically. The product moves up the spiral as the conveyor vibrates.

Vibrating dryer uses indirect heat transfer to cool product while it is conveyed on the dryer surface. Hot water, steam, or hot oil can be used as drying medium. The product and cooling medium are kept separated to ensure product quality and purity.

Vibrating dryer uses indirect heat transfer to cool product while it is conveyed on the dryer surface. Hot water, steam, or hot oil can be used as drying medium. The product and cooling medium are kept separated to ensure product quality and purity.

Vibrating fluid bed dryer uses temperature controlled zones to dry the product quickly and evenly. The product is fluidized in warm or hot air and cooled by convection to achieve high drying rates and excellent uniformity.

Vibrating fluid bed dryer uses temperature controlled zones to dry the product quickly and evenly. The product is fluidized in warm or hot air and cooled by convection to achieve high drying rates and excellent uniformity.

Vibrating fluid bed coolers transfer heat from the product to the cooling medium directly by convection. Either ambient air or cooled air can be used as a cooling medium and mutiple cooling zones are possible.

Vibrating fluid bed coolers transfer heat from the product to the cooling medium directly by convection. Either ambient air or cooled air can be used as a cooling medium and mutiple cooling zones are possible.

Vibrating contact coolers use indirect heat transfer to remove heat from the product. Indirect heat transfer means the product and the heat transfer medium are kept separate. Water or brine can be used as the heat transfer medium. The cooler can be designed with an open feed trough or with an enclosure. The enclosure can be either vibratory or stationary.

Vibrating contact coolers use indirect heat transfer to remove heat from the product. Indirect heat transfer means the product and the heat transfer medium are kept separate. Water or brine can be used as the heat transfer medium. The cooler can be designed with an open feed trough or with an enclosure. The enclosure can be either vibratory or stationary.

The stationary fluidized bed cooler is used to cool chemically bound sand via convective heat exchange with cooling water flowing through tubes.

The stationary fluidized bed cooler is used to cool chemically bound sand via convective heat exchange with cooling water flowing through tubes.

The helical casting cooler simultaneously supports the product and cools it to the desired temperature. The cooling of the product is achieved by exploiting the natural chimney effect via tangentially arranged air jets on the standpipe.

The helical casting cooler simultaneously supports the product and cools it to the desired temperature. The cooling of the product is achieved by exploiting the natural chimney effect via tangentially arranged air jets on the standpipe.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

The circulating air is used for limited cone separator flowing products, wherein the feed material is blown with a defined air flow into the classifier zone. As a result, the particles reduce forces among which high product flow capacities are possible. Classifier diameter about 750, 1000 and 1500mm are available.

The circulating air is used for limited cone separator flowing products, wherein the feed material is blown with a defined air flow into the classifier zone. As a result, the particles reduce forces among which high product flow capacities are possible. Classifier diameter about 750, 1000 and 1500mm are available.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The hybrid classifier uses a patented separator channel that makes it possible to drive speeds even with a very small sifter. This classifier type is mainly used for sorting in the flour and fines range. Working widths from 240 to 900 mm.

The hybrid classifier uses a patented separator channel that makes it possible to drive speeds even with a very small sifter. This classifier type is mainly used for sorting in the flour and fines range. Working widths from 240 to 900 mm.

With the cone separator, after the multi-cross-flow perspective method, in combination with a counter-current inspection, the light material gets separated from heavy. We distinguish: The standard cone separator for free-flowing products is connected via clip on Aspiration with a cyclone and filter system. Classifier diameter of approximately 500, 750 and 1000 mm are possible. The design of the cone separator Dust for effective dusting of plastic granules and pellets is connected via clip on Aspiration with a filtration system. Classifier diameter of approximately 300, 500, 750 and 1,000 mm are possible.

With the cone separator, after the multi-cross-flow perspective method, in combination with a counter-current inspection, the light material gets separated from heavy. We distinguish: The standard cone separator for free-flowing products is connected via clip on Aspiration with a cyclone and filter system. Classifier diameter of approximately 500, 750 and 1000 mm are possible. The design of the cone separator Dust for effective dusting of plastic granules and pellets is connected via clip on Aspiration with a filtration system. Classifier diameter of approximately 300, 500, 750 and 1,000 mm are possible.

The Zig-Zag classifier separates light material from heavy material. Feed material is introduced into the Zig Zag channel via a sealed feeder. The material drops through the channel, cascading from side to side of the channel while forced air flows upward. This cross flow lifts the light particles out the top of the channel while the heavy material falls out the bottom. Working widths from 80 mm to 2.0 m.

The Zig-Zag classifier separates light material from heavy material. Feed material is introduced into the Zig Zag channel via a sealed feeder. The material drops through the channel, cascading from side to side of the channel while forced air flows upward. This cross flow lifts the light particles out the top of the channel while the heavy material falls out the bottom. Working widths from 80 mm to 2.0 m.

With the AirVibe technology, high separation efficiencies of coarse material is possible using a combination of cross flow air separation and ballistic sorting. The AirVibe is a one-stage design with either a stationary divider or a self-cleaning drum design for wet products. Working widths of 600, 1200, 1600, and 2400 mm. The AirVibe 2 offers multiple separation stages. Working width of 1,200 mm.

With the AirVibe technology, high separation efficiencies of coarse material is possible using a combination of cross flow air separation and ballistic sorting. The AirVibe is a one-stage design with either a stationary divider or a self-cleaning drum design for wet products. Working widths of 600, 1200, 1600, and 2400 mm. The AirVibe 2 offers multiple separation stages. Working width of 1,200 mm.

Grizzly screens are used as a primary separator for the preliminary separation of material in front of jaw crushers.

Grizzly screens are used as a primary separator for the preliminary separation of material in front of jaw crushers.

Wet sizing screens are used to increase the separation of fines and achieve accurate cuts. They are also used as washing screens. Wet sizing screens can be designed either as linear or circular motion.

Wet sizing screens are used to increase the separation of fines and achieve accurate cuts. They are also used as washing screens. Wet sizing screens can be designed either as linear or circular motion.

The finger cascade screen TopSpin operates on the basis of a circular vibrating screen with above-average acceleration. The high accelerations work together with the conical opening finger strainer system to create a virtually clog-free strainer for difficult screening applications.

The finger cascade screen TopSpin operates on the basis of a circular vibrating screen with above-average acceleration. The high accelerations work together with the conical opening finger strainer system to create a virtually clog-free strainer for difficult screening applications.

Rod screens are used for pre-separation with large gap widths or for classifying extremely difficult bulk materials which can not be separated on conventional screens.

Rod screens are used for pre-separation with large gap widths or for classifying extremely difficult bulk materials which can not be separated on conventional screens.

Linear motion screens were developed primarily for dewatering and are now used in many industries. With a steep angle and high acceleration, extremely low residual moisture values can be achieved in the dewatered product.

Linear motion screens were developed primarily for dewatering and are now used in many industries. With a steep angle and high acceleration, extremely low residual moisture values can be achieved in the dewatered product.

Banana screens are large, high-strokes screens, developed with the latest technology using the “thin-bed theory” to increase the efficiency in the screening of fines.

Banana screens are large, high-strokes screens, developed with the latest technology using the “thin-bed theory” to increase the efficiency in the screening of fines.

Circular motion screens are used for preliminary or final sizing of medium to coarse-grained bulk materials. The screen moves in a circular motion. Decline angles of 10 to 30 degrees can be set to give optimal throughputs for a wide range of applications.

Circular motion screens are used for preliminary or final sizing of medium to coarse-grained bulk materials. The screen moves in a circular motion. Decline angles of 10 to 30 degrees can be set to give optimal throughputs for a wide range of applications.

Linear vibrating screens are used for the highest separation efficiencies across a wide range of applications and industries. The largest screens in the world allow the highest production rates.

Linear vibrating screens are used for the highest separation efficiencies across a wide range of applications and industries. The largest screens in the world allow the highest production rates.

In the Flip-Flow screen, the elastic screen mats move like a Trampoline. The alternating cross members move relative to each other with a powerful spring mechanism, resulting in a clamping and releasing of the mats.

In the Flip-Flow screen, the elastic screen mats move like a Trampoline. The alternating cross members move relative to each other with a powerful spring mechanism, resulting in a clamping and releasing of the mats.EJV has 2 covered Sheds. All Bays have got height 12 metres below the Crane Hook. Both bays have a span of 27m. Length of the first Bay is 95 m and 2nd bay length is 53 m. Uncovered area is about 100,000 sq.ft.

First Shed

First Shed is equipped with 40 T (20/20) EOT Crane, 5T additional E.O.T. Crane and 6 nos. Jib Cranes mounted on the columns. There is also a 10T Mobile Crane, to shift the raw material from outside storage area to the Shop. Facilities available here are : Heavy Duty Shearing Machine, Heavy Duty Bending Machine, and a Shot Blasting and Painting Booth. Isolation Bays for testing Vibratory equipments.

First Shed is equipped with 40 T (20/20) EOT Crane, 5T additional E.O.T. Crane and 6 nos. Jib Cranes mounted on the columns. There is also a 10T Mobile Crane, to shift the raw material from outside storage area to the Shop. Facilities available here are : Heavy Duty Shearing Machine, Heavy Duty Bending Machine, and a Shot Blasting and Painting Booth. Isolation Bays for testing Vibratory equipments.

Second Shed

Second Shed is equipped with 20/5 Ton EOT Crane. Facilities available here are:

Second Shed is equipped with 20/5 Ton EOT Crane. Facilities available here are:

CNC Plasma/Oxy Acetylene Cutting Machine. Isolation Bays for testing Vibratory equipment and testing facilities for Magnetic Feeders, Excitor Drives, Unbalance Motors, Feeders, large Screens.

EJV has CO2 and manual arc welding machines.

EJV has a ready access to some machines of its Partner EDPL. These include a Kuka Robot, CNC Press Brakes, CNC Shearing Machine, Waterjet Machine, Vertical Turning Centre, Plano Miller, Punch Presses (for punching stampings for magnetic drive) and conventional small horizontal Boring Machine.

Bed size of 6m * 2m ,Sheet Metal Cutting upto 16mm and 42mm with Gas Cutting.

Bed size of 6m * 2m ,Sheet Metal Cutting upto 16mm and 42mm with Gas Cutting. Light Assembly Shop in Mumbai has induction heating element, light press, light machines and fixtures for assembly of motors and exciters.

Light Assembly Shop in Mumbai has induction heating element, light press, light machines and fixtures for assembly of motors and exciters. Bed size of 4m * 3m ,Sheet Metal Cutting upto 120mm.

Bed size of 4m * 3m ,Sheet Metal Cutting upto 120mm. Vibration shakeout drums are generally located directly after the cast form a wet ball ejector system. From vibrations of suitable parameters with high acceleration, the separation of casting and molding sand. Unpacking the tube is at the end of the machine body is provided with a case, the use of customized grid surface, through which the used sand is discharged downwards. Unpacking pipes are suitable for castings, the outside have no fragile ribs or thin walls.

Vibration shakeout drums are generally located directly after the cast form a wet ball ejector system. From vibrations of suitable parameters with high acceleration, the separation of casting and molding sand. Unpacking the tube is at the end of the machine body is provided with a case, the use of customized grid surface, through which the used sand is discharged downwards. Unpacking pipes are suitable for castings, the outside have no fragile ribs or thin walls. Furnace Charger for feeding to furnaces in foundry & steel melting shops.

Furnace Charger for feeding to furnaces in foundry & steel melting shops. Dosing feeders are used for small applications or as hopper discharge feeders. Highly accurate control of the feed rate is possible with the electro-magnetic drive and the infinitely variable thyristor controller.

Dosing feeders are used for small applications or as hopper discharge feeders. Highly accurate control of the feed rate is possible with the electro-magnetic drive and the infinitely variable thyristor controller. Hopper discharge feeders with integral feed chutes for feeder from bunkers or hoppers are available in various designs. The FUFB deisgn uses unbalanced motors while the FRFB design has an exciter and a separate electric motor for high capacities and heavy products. Vibration amplitude of the feeder can be fixed or adjusted with a variable frequency drive.

Hopper discharge feeders with integral feed chutes for feeder from bunkers or hoppers are available in various designs. The FUFB deisgn uses unbalanced motors while the FRFB design has an exciter and a separate electric motor for high capacities and heavy products. Vibration amplitude of the feeder can be fixed or adjusted with a variable frequency drive. Gate feeders allow the pumping of sand castings or, depending on the parameters, either by gutter output left or right gutter output. The switching process takes place only at the electrical control instead.

Gate feeders allow the pumping of sand castings or, depending on the parameters, either by gutter output left or right gutter output. The switching process takes place only at the electrical control instead. Sand transport gutters are used in foundries below separation gutters to transport the used sand over longer distances in the direction of sand preparation. The design as a response channel will apply if the length exceeds approximately 8 meters and thus an imbalance channel can not be used.

Sand transport gutters are used in foundries below separation gutters to transport the used sand over longer distances in the direction of sand preparation. The design as a response channel will apply if the length exceeds approximately 8 meters and thus an imbalance channel can not be used. Mould Dump conveyors are mass-compensated low-speed resonance channels with low acceleration values. The trough is made of Wear-Resistant steel. Complex lines with curves, climbs, and switches can be realized. Low noise levels are obtained by avoiding throwing motion.

Mould Dump conveyors are mass-compensated low-speed resonance channels with low acceleration values. The trough is made of Wear-Resistant steel. Complex lines with curves, climbs, and switches can be realized. Low noise levels are obtained by avoiding throwing motion. Sorting/Casting conveyors are mass-compensated low-speed resonance channels with low acceleration values and low flow velocities. The trough is made of wear-resistant steel reinforced walls. On these machines, the casting is separated from the gate or feeder. Quiet, smooth transportation without micro throwing motion.

Sorting/Casting conveyors are mass-compensated low-speed resonance channels with low acceleration values and low flow velocities. The trough is made of wear-resistant steel reinforced walls. On these machines, the casting is separated from the gate or feeder. Quiet, smooth transportation without micro throwing motion.

Shakeouts are generally placed directly after the ball ejector of a green sand molding line. The separation of casting and molding sand is carried out by high-frequency vibrations of suitable parameters with high acceleration. The separation channel is provided with a case with a customized grid surface through which the used sand is discharged downwards.