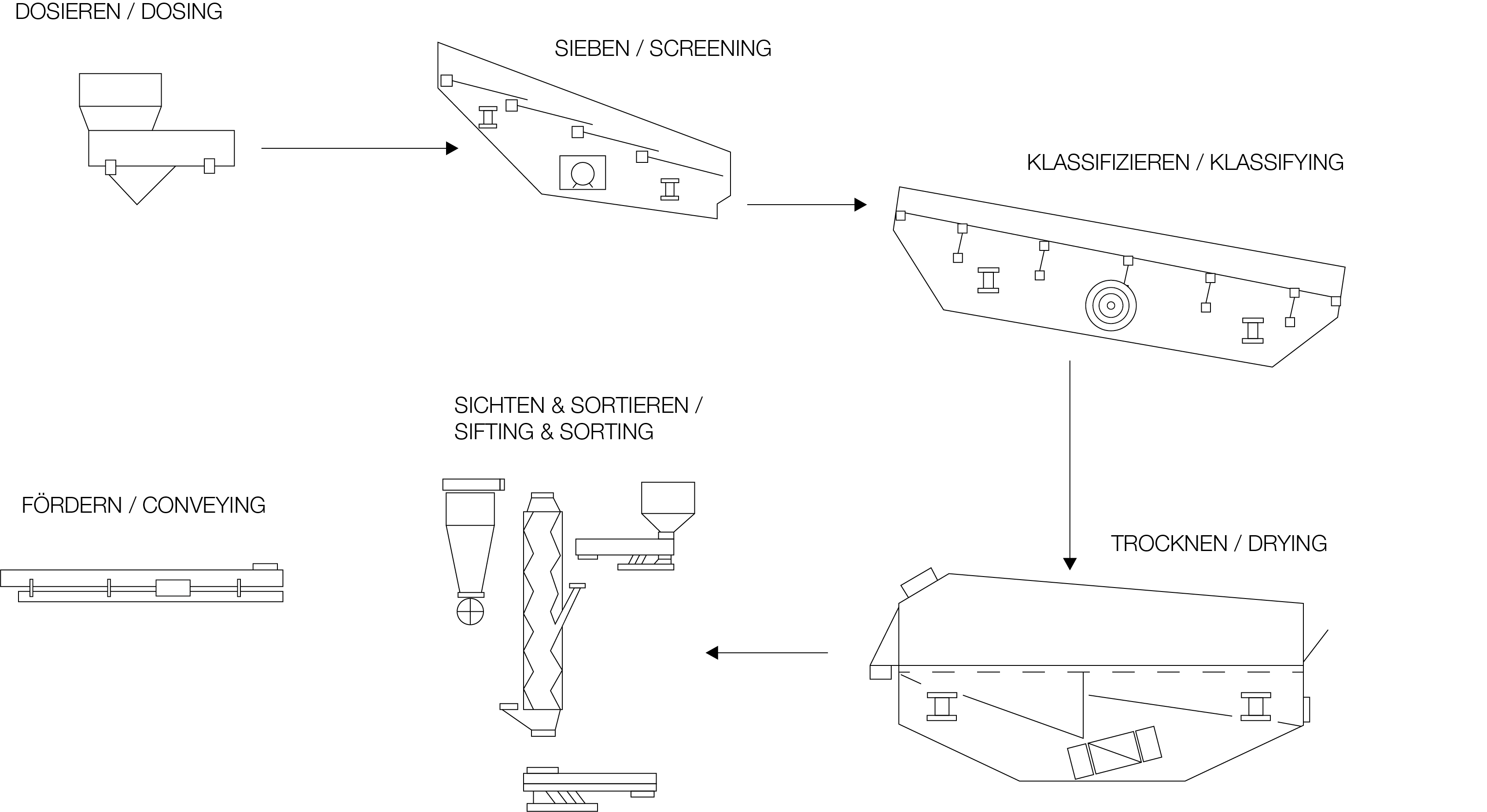

Recycling is a growing market – especially in glass recycling new plants are cur- rently arising or existing ones are updated and upgraded. JOEST is an expert for vibratory equipment conveying and processing bulk materials. As such, JOEST offers plant manufacturers customized solutions for glass recycling. With dosing, screening, drying, sifting and conveying, the company covers five fundamental processing steps in a plant.

Thanks to the continuous development of standardized components and subsystems, the JOEST competence center recycling in Duelmen can assist each client with the individual configuration of their plant layout, especially regarding the procedural design of the individual processing components.

dosing

screening

drying

sifting

conveying

JOEST covers a wide spectrum of applied tech- nologies throughout the glass recycling process and simultaneously goes in depth with various versions as well as the corresponding periphery. The individual components are specifically designed for the demands of each industry and size, performance and features are determined by the client. The operational avail- ability of the plant is very important. In particular the high wear resistance, thus the low abrasion of plant components plays a big role in Glass Recycling since glass brakes and is one of the most abrasive materials. Using highly wear resistant chromium carbide plates or special ceramic, the machines set standards and ensure high runtimes and yet low maintenance costs.

From bottle caps and labels to cardboard and plastic: Glass waste can contain up to 50 % organic and waste materials. Depending on this composition and the final desired quality of the recycled material, a variety of sorting processes are necessary. The first step is to convey and dose the glass waste out of the hopper. JOEST magnetic feeders are ideal for such an application, since the feed rate is continuously variable and after being shut down, the machine stops immediately. In addition, the JOEST Hopper Discharge Feeders use an innova- tive, self adjusting JM-Magnetic Drive. With relatively high amplitude in combination with a comparably average vibration frequency, this drive system results in an efficient discharge. For their particular application, different parameters such as hopper pressure and geom- etry, grain size, ease of flow, moisture and tendency to bake-on must be considered. The optional covers and discharge hoods are also specifically designed for Glass Recycling. The drive´s self learning mode, enabled by the digital control unit, is as easy to maintain as it is economically efficient. This JM-Drive is an exclusive and unique JOEST product in the world market.

Special JOEST Finger Screens pre-classify the glass waste into cross cuts between 10 and 40 mm grain size. The high acceleration rates and oscillation of the fingers loosen the material on the screen deck. They also ensure a near clog free screening process.

Fine fractions are screened out, coarse grain continues on to a crusher. In another processing step, the JOEST Air Vibe separates the first material flow and sorts out the coarse light weight fraction like foils or paper for example.

The JOEST Flip-Flow-Screen is designed for inho- mogeneous or moist and thus difficult to screen materials. Particularly glass waste has varying levels of contamination with organic material, depending on the country and region it originates from. Here, the OSCILLA Flip-Flow-Screen provides ideal precondi- tions with a feed grain size of 0 to 80 mm. With its trampoline-effect, this special process prevents the product from sticking on and near-mesh grain from getting clog the sieve. The elastic screen mats which are fixed under tension with the traverse mutually beams and thus the dynamic frame and screen body, are decisive to the process.

The low maintenance is just as beneficial. Changing over the mats is quick and easy to do. In the new- est OSCILLA generation, JOEST implements viroblocks between the dynamic frame and the screen body, following the demand for a simple, cost efficient, yet robust solution. The traverse beams also feature special profils to ensure flexibility and efficiency. They are simply cut to the desired length and bolted to the machine body.

The raw material in Glass Recycling contains about 7 % moisture.This moisture sticks to the product and complicates processing it. A drying stage eases further processing. For this purpose, JOEST uses a Fluidized Bed Dryer. With airstreams of more than 150 °C, it reduces the moisture level to a target value of 1 %. Thanks to the special design and layout of the air distribution chamber(s), the air passes evenly through the material and thus results in an equally even dry- ing result. The conveyance within the dryer occurs via micro throwing motions, which are characteristic for vibration conveying technology. Amplitude, fre- quency and throwing angle are adjusted individually to the application and machine type. Additionally, air outlet hoods are available and follow the motion of the machine. JOEST delivers anything from the machine alone all the way to the entire drying plant including air handling equipment, air filtration, duct- work, steel construction and electrical control unit.

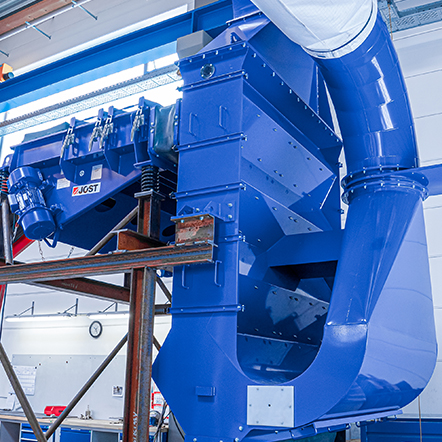

Inside the Zig-Zag Sifter, a multi stage separation of organic material from the individual pre-classified fractions takes place – the goal is an entire elimina- tion of pollution from the raw material. In order to achieve this, the raw material is fed into the zig-zag shaped sifter-channel through an air-tight feed- ing mechanism. After the Multi Cross Flow Sifting Process, the light weight fraction separates itself from the heavy fraction.The Zig-Zag Sifter is also adapted to the glass material in abration intensive areas. Thus the JOEST Zig-Zag Sifter uses a Vibrating Trough Type Feeder, as opposed to a Rotary Feeder. This results in an even distribution across the width of the machine and feeding of the machine, whilst keeping the wear resistance high. Here too, JOEST offers the complete system with air handling equipment, used air filtration, pipelines, steel construction and electri- cal control unit.

Depending on the glass recycling plant, there are different demands: Covering distance, feeding and distributing. For this, JOEST offers the matching drive technologies, like for example Unbalanced- or Resonance Vibrating Trough Type Feeders. All Trough Type Feeders feature an abrasion resistant lining and can be configured as dust tight if the client wishes so. In general, conveying stretches of up to 80 meters with a single machine are possible. Appropriate solu- tions for shorter distances with difficult installation situations can also be carried out.