INTERVIEW. 100 years of JOEST next year – Interview with Managing Director, Dr. Marcus Wirtz

These are turbulent times – the Diesel emmission scandal, political shocks, e-mobility and Industry 4.0 challenge the foundries.

Nevertheless, JOEST continues to write its success story unabashed. Rising sales and employee figures show that the company is doing a lot right. JOEST can confidently look forward to its 100th anniversary next year. How did the company from Duelmen achieve this? GIESSEREI spoke to the JOEST Managing Director, Dr. Marcus Wirtz.

Your company is successful in the market and boasts increasing sales and employee figures. You obviously did a lot of things right. In your opinion, what was decisive for this development?

One of the key aspects of our success story is the history of the company. JOEST celebrates its 100th anniversary next year. We have remained true to ourselves throughout the years. We have been manufacturing vibratory machines for a long time, but have remained open-minded and have added additional technologies to our portfolio. We have developed these consistently and made it possible for the company to continue to grow in a generic and organic way with new applications and technologies. Today we offer everything the market asks for – from small individual machines to large solutions. We fulfill the wishes of many foundries with complete solutions. We have developed ourselves in line with the customers and their needs. Listening and counseling is essential – and of course experience.

What were the milestones in the development of JOEST? To steadily strengthen its growth, JOEST has made acquisitions that are optimally suited. In 1995, we acquired the Uhde-Schwingungstechnik. Herweg joined in 2002: In addition to the vibration technology, JOEST now also offers weighing technology and special solutions. The conveying in vacuum was made possible. In 2006, JOEST took over DIETERLE, a manufacturer of lifting and tipping equipment that transports, lifts, tilts, doses or decants bulk materials. DIETERLE GmbH & Co. KG merged with JOEST GmbH + Co. KG early 2018 and is no longer an independent company, but another strong JOEST group brand. In this way, we have expanded and supplemented our portfolio, and now offer an even wider range of products.

A company is only successful in a team. What is the role of your employees in the growth?

Naturally, our employees are central to our success. We attach great importance to employing primarily foundry engineers in our foundry division or employees from the foundry sector. Everyone carries the foundry DNA in themselves. This allows for a completely different access to customers. Furthermore, JOEST has a very good staff structure of older and younger employees, from experienced and talented employees. Today, having on-site contact is more important than ever in international business. We have a total of ten subsidiaries. At least one on each continent, where we also manufacture, have spare parts ready and employ engineers. A key success of the JOEST group lies in the successful internationalization strategy of the last 20 years. Now we are present in different countries and keep a close eye on what each country needs. This global presence also makes it possible to balance a weakening market with a stronger one.

How does success translate into numbers?

The success can be seen in the development of sales and employee figures. They rose by 10 to 15 percent respectively in the past three years. Today, JOEST has 365 employees in Germany – 15 more than a year and a half ago. Sales worldwide rose to more than 90 million euros.

Good numbers despite adversity – the Diesel emmission scandal also had an impact on the suppliers to the automotive industry. How did it impact JOEST?

Of course, the exhaust gas scandal has damaged the image of German mechanical engineering. At first there were irritations, projects were sometimes postponed. But there were reinvestments, the irritations are only insignificant. The scandal was so far not as significant as expected. We were able to balance the dent with other applications. Especially since the European foundries are becoming more and more international.

What impact do growing expectations for efficiency and sustainability have on your business?

We pay attention, for example, to efficiency in drive technology, which has always been one of our core competencies. An example: We have produced a large cast iron cooler – the largest vibrating machine in Europe – which is only powered by a 15 KW motor. We lower the energy consumption, even as the cast coolers get larger and larger. In addition, we at JOEST naturally optimize our own production processes and production halls. The conversion to state-of-the-art technology, such as LED lighting and cold-beam heating systems, significantly saves on energy.

How did you manage to meet the increasing demands?

In fact, the requirements are becoming more and more complex – but we enjoy tackling them. To do this, we develop new processes and optimize machines, controls and plant technology. This applies for example to the core sand crushing. In order to meet high requirements, we have also steadily increased our development staff. We also offer a dual degree program, which we are significantly expanding for the different areas. In addition, we are preparing ourselves as a strong training company for the future. We currently have 35 trainees – from the commercial sector to production. As customers increasingly demand a local presence, JOEST founded another new company in Korea in 2017. In China and Korea, there is a clear demand to produce locally, which we also live up to. We are well informed about different countries and we have a combination of local and international staff here.

Business units usually do not all develop at the same pace. Which product portfolio for foundries shows a particularly strong growth at your company?

What are the reasons?

A current trend is that due to increasing demand, several brake disk foundries are investing in box form plants with horizontal division in order to produce the castings with a structure which is point symmetrical to its axis of rotation. The configuration of the molding boxes is maximized; the performance of modern molding equipment is significant. This requires casting/sand separation plants in appropriate dimensions. In the production of engine blocks made of cast iron materials increasingly methods are used in which the casting has no direct contact with the wet casting sand, but rather is enclosed by an outer contour core structure to meet the accuracy and reproducibility, demanded by the required thin casting wall thicknesses of up to 2.5 mm. Such filigree castings require special unpacking procedures. This can not be managed with conventional separation channels. In the production of aluminum cylinder heads and several components for electric cars in gravity die casting, the cavities of the castings are mapped by built cores. For reasons of emission protection, increasingly inorganic binders are used for the production of these cores, replacing the traditional organic cold box process. It has been found, however, that the dust produced during the various post-coring process steps is significantly finer and partially respirable, i.e., penetrates into the alveoli. This considerably raises the demands placed on the plant technology with regard to dust-proofness and wear resistance. Since our concepts consistently reflect the indispensable feedback of customer experience, we have suitable solutions that meet these requirements.

Which markets may come to the fore?

We can see expansions in Mexico and Turkey. The automotive industry is growing, increasing the need for foundries. Especially since end users expect the foundry to be located nearby. In addition, there is an investment backlog in North America. Much of the production was shifted especially to China. Now a lot can come back. The political and financial problems and conflicts – recently in Turkey – as well as tweets from the US, however, can stop such developments overnight and lead to shifts to other countries. Therefore, our international presence is essential.

E-mobility is thus coming increasingly into the spotlight. How do you rate this market?

It will be a long time before there are no more combustion engines left. The demand for trucks is very high.

Truck transport is increasing enormously and e-mobility is less important here and will not represent a solution for the foreseeable future. I consider the goals of e-mobility announced by politicians in Germany to be unrealistic. But I have the impression that this will calm down and they will come to their senses, to more realistic assessments and time frames. (Including combustion engine). This includes hydrogen propulsion and the classic internal combustion engine in other regions, where these are constantly optimized. To meet future requirements for fleet consumption

The share of hybrid drives will rise significantly in the coming years. This requires about 25 to 30 percent more weight in castings. According to expert estimates, this trend will continue until at least 2035. If the share of pure electric vehicles increases gradually, the proportion of castings will decrease significantly, but many castings will be required for the charging infrastructure and the growing number of wind turbines.

Could markets develop differently? In China, North America – and Africa in the long term – the demand for engines is immense, and the distances to be covered are even greater. The internal combustion engines will continue to play their part in this. But one thing is clear: E-mobility is a trend, the share of E-mobility will continue to grow. There will be a mix: in the urban area rather electric motors and hybrid technology (with internal combustion engine). This includes hydrogen propulsion and the classic internal combustion engine in other regions, where these are constantly optimized. In order to meet future requirements for fleet consumption, the share of hybrid drives will increase significantly in the coming years. This requires about 25 to 30 percent more weight in castings. According to expert estimates, this trend will continue until at least 2035. If the share of pure electric vehicles increases gradually, the proportion of castings will decrease significantly, but many castings will be required for the charging infrastructure and the growing number of wind turbines.

Industry 4.0 is the future. How do you position yourself here?

Industry 4.0 is a special opportunity, we are working intensively with it. We have already developed some solutions: Thus, we provide a clear allocation of data on the castings, bring together numerous parameters and allow tracing of data. For example, the customer knows where things are. The goal is to detect mistakes earlier and avoid them. It’s all about reporting of faults, avoidance of failures and preventive maintenance. Our vision is that you can tell why a casting error occurred. All data – such as temperature, speed, humidity, inventory and noise level – should be merged. An important example: The controllers we develop should not just control. We already have intelligent controls – the platform is there, so the hardware is there. Now let’s see how we use them, so that these controls can unfold their full potential. For this purpose, the controllers are additionally equipped with intelligent software. We want to offer both: normal and intelligent controls.

Without innovations there is no further development of the company. With what strategy do you proceed here?

The field of research and development is essential for us. That is why we work together with various universities, for example with the Technical University of Aachen and the University of Applied Sciences of Münster, Steinfurt department. We award master’s and doctoral theses. Furthermore, I am a member of the board of the VDMA trade association

Metallurgy and Chairman of the Department of Mineral Processing. Here, global strategic issues are discussed.

What investments did you use to accelerate the development of your company?

We have been here in Dülmen since 1990 and have since been constantly expanding by investing in new plants and production capacities such as halls. The floor area increased from 40,000 to approximately 65,000 square meters. An example: Eight years ago, we built a completely new blasting and

painting plant using state-of-the-art technology. Since then we can perform all paint specifications up to the highest quality requirements in a flexible and timely manner. This is especially important when offering premium quality with short delivery times. On November 1, the new technical center went into operation. We built this even larger. Here we can run tests with customers for all solutions as well as machines and prototypes offered by JOEST. Over the past few years, we have invested a total of more than 10 million euros in our main site in Dülmen.

Are there plans for further investment in the next few years?

Yes, this includes, for example, the new machine technology of the flame cutting machine with integrated machining centers. We also employ welding robots to achieve productivity at a consistently high level of quality. As the world leader in vibration technology with manufacturing facilities on every continent, quality is our top priority, no matter where in the world customers buy from us. Therefore, we continue to focus on Germany and plan further expansions, especially for quality-critical parts and components.

Investments are important, but also require qualified employees. How do you deal with the shortage of skilled workers?

We must note that it is becoming more difficult to find trainees. This applies especially to the field of electrical engineering. Basically, we are working very actively to avoid a shortage of skilled workers. Thus, for example, we have a good network with associations and universities. And we can offer employees many benefits. We have very good transport connections. We are in close proximity to Münster as well as Duisburg, Dortmund and Dusseldorf – without having to renounce the advantages of inexpensive rural living. A great location advantage. The dual course of study that we offer is also very attractive. Young employees have many and good international opportunities for development. Out of consideration for the families, the fitters are still working in the factory. The employees assemble the machines here, but then accompany them to the construction site for final assembly. It is important for us not only to keep our employees, but to offer an attractive, motivating work environment with prospects. And this is confirmed by the fact that they want to stay here!

The interview was conducted by Michael Vehreschild, 4P Communications, Kleve. The article was published in 12/2018 issue of GIESSEREI professional journal.

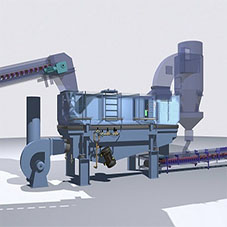

Sand attrition units type ZUFS are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler. Powerful, linear vibrations are disintegrating the lumps in the attrition sink and repulverize them to sand. Following the attrition sink the oversize grains are screened out with an easy to maintain mounted, well accessible and visible fine screen.

Sand attrition units type ZUFS are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler. Powerful, linear vibrations are disintegrating the lumps in the attrition sink and repulverize them to sand. Following the attrition sink the oversize grains are screened out with an easy to maintain mounted, well accessible and visible fine screen. The ZUFB machines are pre-reclaiming sand attrition units (Vibro V-jaw crusher) for big lumps of chemical bonded moulding and core sand. They are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable. The result: Small sand lumps, ready for further attrition. Note: A friction-based reclaiming unit model ZUFS needs to be installed after a ZUFB sand attrition unit. If high quantities of metal are embedded in the processed sand lumps, it is necessary to remove them before they enter the device.

The ZUFB machines are pre-reclaiming sand attrition units (Vibro V-jaw crusher) for big lumps of chemical bonded moulding and core sand. They are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable. The result: Small sand lumps, ready for further attrition. Note: A friction-based reclaiming unit model ZUFS needs to be installed after a ZUFB sand attrition unit. If high quantities of metal are embedded in the processed sand lumps, it is necessary to remove them before they enter the device. Furan sand reclamation plants for cold resin bonded sand. The available perfomance is from 1 t/h up to 20 t/h in single line applications. The available screen deck size range is up to 4500 x 4500 mm / 50 ton deck load in single deck applications.

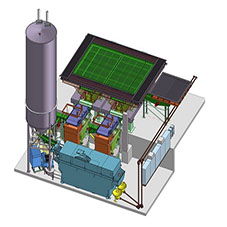

Furan sand reclamation plants for cold resin bonded sand. The available perfomance is from 1 t/h up to 20 t/h in single line applications. The available screen deck size range is up to 4500 x 4500 mm / 50 ton deck load in single deck applications.

Vibrating tables are used to compact various bulk materials, i.e. cold resin bonded moulding sand in nobake mouldlines. Jöst supplies vibrating tables combined with suitable roller track sections; this combo can be placed directly underneath the whirl mixer swivel range.

Vibrating tables are used to compact various bulk materials, i.e. cold resin bonded moulding sand in nobake mouldlines. Jöst supplies vibrating tables combined with suitable roller track sections; this combo can be placed directly underneath the whirl mixer swivel range.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The counter-current setback classifier is used for screening of chemically bonded sand. This means that the organic binder components that are abraded from the sand grain surface before the classifier (such as by a tube shredder) are removed as much as possible. Accordingly, the loss on ignition is greatly reduced. Lowering classifiers are usually part of cold sand resin regeneration plants.

The fluid bed cooler cools down the moulding sand which is conveyed from a crusher through an upstream magnetic drum into the cooler. The machine is not vibrating but stationary. The sand is fluidised by means of a special fluidisation plate by a powerful vertical air flow. It then has flow characteristics like water. When fluidised, the heat is released via contact heat exchange to a tube matrix with high surface passed by water.

The fluid bed cooler cools down the moulding sand which is conveyed from a crusher through an upstream magnetic drum into the cooler. The machine is not vibrating but stationary. The sand is fluidised by means of a special fluidisation plate by a powerful vertical air flow. It then has flow characteristics like water. When fluidised, the heat is released via contact heat exchange to a tube matrix with high surface passed by water.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

The spiral breaker is designed for unmoulding cold resin bonded sand moulds on its shakeout deck surface by powerful, directed vibrations. Furthermore, the sand lumps are disintegrated in the lower deck which is located the crusher body. The reclaimed sand is conveyed upwards to gain hight in a helical shaped trough which surrounds the machine body.

Sand attrition units are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler.

Sand attrition units are very powerful and compact machines for chemically bonded mould and core sand. These proved and tested machines are often used in well-known foundries. Generally the sand attrition units are integrated in sand reclamation plants between shake-out and sand cooler.

The pre-reclaiming sand attrition units for big lumps of organic bonded moulding and core sand are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable.

The pre-reclaiming sand attrition units for big lumps of organic bonded moulding and core sand are typically used for the primary reduction of core sand blocks. The sand block is mainly destroyed by squeezing it between two vibrating jaws. The width of the outlet gap is adjustable.

Shakeout screens are machines which are equipped with a heavy duty deck. The vibration features high acceleration and is directed vertically. This enables the machine to shake out nobake sand moulds.

Shakeout screens are machines which are equipped with a heavy duty deck. The vibration features high acceleration and is directed vertically. This enables the machine to shake out nobake sand moulds.

Used sand coolers serve for the cooling of hot foundry sand. The sand cooler consists of a vibrating conveyor made with an air-permeable bottom, a stationary exhaust hood, a moisturizing unit, a fan and a control unit. The sand is cooled under optimum heat transfer conditions in the fluidised bed by evaporation of water. The final moisture level is adjusted by the precisely controlled addition of water according to the temperature and throughput.

Used sand coolers serve for the cooling of hot foundry sand. The sand cooler consists of a vibrating conveyor made with an air-permeable bottom, a stationary exhaust hood, a moisturizing unit, a fan and a control unit. The sand is cooled under optimum heat transfer conditions in the fluidised bed by evaporation of water. The final moisture level is adjusted by the precisely controlled addition of water according to the temperature and throughput.

Gate feeders, which are especially suitable for the cast iron transport, are basically consisting of the vibrating trough, the trough carrying frame and the modular executed and standardised vibration absorber stations. The flexibility of the design allows a large distance between the absorber stations.

Gate feeders, which are especially suitable for the cast iron transport, are basically consisting of the vibrating trough, the trough carrying frame and the modular executed and standardised vibration absorber stations. The flexibility of the design allows a large distance between the absorber stations.

Sand conveyors are used below shakeout machines to convey the used sand over long distances in direction to the place where the sand is treated.

Sand conveyors are used below shakeout machines to convey the used sand over long distances in direction to the place where the sand is treated.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Sorting conveyors are robustly manufactured special vibrating conveyors. They are normally used in foundries with green sand mould line installations. The sorting conveyors are installed either directly after a separating conveyor or ideally directly after a casting cooler.

Due to vibration parameters, selected accordingly, the castings on a helical casting cooler are conveyed downwards. The cooling is effected by means of a convection heat exchange in counter flow.

Due to vibration parameters, selected accordingly, the castings on a helical casting cooler are conveyed downwards. The cooling is effected by means of a convection heat exchange in counter flow.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

Casting coolers are heavy duty slow speed resonance conveyors which are equipped with an airtight hood. Typically, this machine is arranged after the shakeout. The cooling effect is based on convective heat exchange between the hot castings and a powerful cooling air flow.

Vibration shakeout drums are used, when the castings which have to be unpacked, are small and have few fins on the outside. When unpacking the castings, they will slightly collide with each other due to vibrations. Shakeout drums are mainly installed after vertically divided flaskless mouldlines.

Vibration shakeout drums are used, when the castings which have to be unpacked, are small and have few fins on the outside. When unpacking the castings, they will slightly collide with each other due to vibrations. Shakeout drums are mainly installed after vertically divided flaskless mouldlines.

The shakeout machines are equipped with an electronically adjustable angle of attack. Typically they are installed directly after a green sand mouldline. These proved machines are in a high quantity in practical operation in noted foundries. In general the machines are in use when sensitive cast parts needs to be unpacked.

The shakeout machines are equipped with an electronically adjustable angle of attack. Typically they are installed directly after a green sand mouldline. These proved machines are in a high quantity in practical operation in noted foundries. In general the machines are in use when sensitive cast parts needs to be unpacked.

The spiral conveyor is a special type of vibratory conveyor that lifts product vertically. The product moves up the spiral as the conveyor vibrates.

The spiral conveyor is a special type of vibratory conveyor that lifts product vertically. The product moves up the spiral as the conveyor vibrates.

Vibrating dryer uses indirect heat transfer to cool product while it is conveyed on the dryer surface. Hot water, steam, or hot oil can be used as drying medium. The product and cooling medium are kept separated to ensure product quality and purity.

Vibrating dryer uses indirect heat transfer to cool product while it is conveyed on the dryer surface. Hot water, steam, or hot oil can be used as drying medium. The product and cooling medium are kept separated to ensure product quality and purity.

Vibrating fluid bed dryer uses temperature controlled zones to dry the product quickly and evenly. The product is fluidized in warm or hot air and cooled by convection to achieve high drying rates and excellent uniformity.

Vibrating fluid bed dryer uses temperature controlled zones to dry the product quickly and evenly. The product is fluidized in warm or hot air and cooled by convection to achieve high drying rates and excellent uniformity.

Vibrating fluid bed coolers transfer heat from the product to the cooling medium directly by convection. Either ambient air or cooled air can be used as a cooling medium and mutiple cooling zones are possible.

Vibrating fluid bed coolers transfer heat from the product to the cooling medium directly by convection. Either ambient air or cooled air can be used as a cooling medium and mutiple cooling zones are possible.

Vibrating contact coolers use indirect heat transfer to remove heat from the product. Indirect heat transfer means the product and the heat transfer medium are kept separate. Water or brine can be used as the heat transfer medium. The cooler can be designed with an open feed trough or with an enclosure. The enclosure can be either vibratory or stationary.

Vibrating contact coolers use indirect heat transfer to remove heat from the product. Indirect heat transfer means the product and the heat transfer medium are kept separate. Water or brine can be used as the heat transfer medium. The cooler can be designed with an open feed trough or with an enclosure. The enclosure can be either vibratory or stationary.

The stationary fluidized bed cooler is used to cool chemically bound sand via convective heat exchange with cooling water flowing through tubes.

The stationary fluidized bed cooler is used to cool chemically bound sand via convective heat exchange with cooling water flowing through tubes.

The helical casting cooler simultaneously supports the product and cools it to the desired temperature. The cooling of the product is achieved by exploiting the natural chimney effect via tangentially arranged air jets on the standpipe.

The helical casting cooler simultaneously supports the product and cools it to the desired temperature. The cooling of the product is achieved by exploiting the natural chimney effect via tangentially arranged air jets on the standpipe.

The circulating air is used for limited cone separator flowing products, wherein the feed material is blown with a defined air flow into the classifier zone. As a result, the particles reduce forces among which high product flow capacities are possible. Classifier diameter about 750, 1000 and 1500mm are available.

The circulating air is used for limited cone separator flowing products, wherein the feed material is blown with a defined air flow into the classifier zone. As a result, the particles reduce forces among which high product flow capacities are possible. Classifier diameter about 750, 1000 and 1500mm are available.

The hybrid classifier uses a patented separator channel that makes it possible to drive speeds even with a very small sifter. This classifier type is mainly used for sorting in the flour and fines range. Working widths from 240 to 900 mm.

The hybrid classifier uses a patented separator channel that makes it possible to drive speeds even with a very small sifter. This classifier type is mainly used for sorting in the flour and fines range. Working widths from 240 to 900 mm.

With the cone separator, after the multi-cross-flow perspective method, in combination with a counter-current inspection, the light material gets separated from heavy. We distinguish: The standard cone separator for free-flowing products is connected via clip on Aspiration with a cyclone and filter system. Classifier diameter of approximately 500, 750 and 1000 mm are possible. The design of the cone separator Dust for effective dusting of plastic granules and pellets is connected via clip on Aspiration with a filtration system. Classifier diameter of approximately 300, 500, 750 and 1,000 mm are possible.

With the cone separator, after the multi-cross-flow perspective method, in combination with a counter-current inspection, the light material gets separated from heavy. We distinguish: The standard cone separator for free-flowing products is connected via clip on Aspiration with a cyclone and filter system. Classifier diameter of approximately 500, 750 and 1000 mm are possible. The design of the cone separator Dust for effective dusting of plastic granules and pellets is connected via clip on Aspiration with a filtration system. Classifier diameter of approximately 300, 500, 750 and 1,000 mm are possible.

The Zig-Zag classifier separates light material from heavy material. Feed material is introduced into the Zig Zag channel via a sealed feeder. The material drops through the channel, cascading from side to side of the channel while forced air flows upward. This cross flow lifts the light particles out the top of the channel while the heavy material falls out the bottom. Working widths from 80 mm to 2.0 m.

The Zig-Zag classifier separates light material from heavy material. Feed material is introduced into the Zig Zag channel via a sealed feeder. The material drops through the channel, cascading from side to side of the channel while forced air flows upward. This cross flow lifts the light particles out the top of the channel while the heavy material falls out the bottom. Working widths from 80 mm to 2.0 m.

With the AirVibe technology, high separation efficiencies of coarse material is possible using a combination of cross flow air separation and ballistic sorting. The AirVibe is a one-stage design with either a stationary divider or a self-cleaning drum design for wet products. Working widths of 600, 1200, 1600, and 2400 mm. The AirVibe 2 offers multiple separation stages. Working width of 1,200 mm.

With the AirVibe technology, high separation efficiencies of coarse material is possible using a combination of cross flow air separation and ballistic sorting. The AirVibe is a one-stage design with either a stationary divider or a self-cleaning drum design for wet products. Working widths of 600, 1200, 1600, and 2400 mm. The AirVibe 2 offers multiple separation stages. Working width of 1,200 mm.

Grizzly screens are used as a primary separator for the preliminary separation of material in front of jaw crushers.

Grizzly screens are used as a primary separator for the preliminary separation of material in front of jaw crushers.

Wet sizing screens are used to increase the separation of fines and achieve accurate cuts. They are also used as washing screens. Wet sizing screens can be designed either as linear or circular motion.

Wet sizing screens are used to increase the separation of fines and achieve accurate cuts. They are also used as washing screens. Wet sizing screens can be designed either as linear or circular motion.

The finger cascade screen TopSpin operates on the basis of a circular vibrating screen with above-average acceleration. The high accelerations work together with the conical opening finger strainer system to create a virtually clog-free strainer for difficult screening applications.

The finger cascade screen TopSpin operates on the basis of a circular vibrating screen with above-average acceleration. The high accelerations work together with the conical opening finger strainer system to create a virtually clog-free strainer for difficult screening applications.

Rod screens are used for pre-separation with large gap widths or for classifying extremely difficult bulk materials which can not be separated on conventional screens.

Rod screens are used for pre-separation with large gap widths or for classifying extremely difficult bulk materials which can not be separated on conventional screens.

Linear motion screens were developed primarily for dewatering and are now used in many industries. With a steep angle and high acceleration, extremely low residual moisture values can be achieved in the dewatered product.

Linear motion screens were developed primarily for dewatering and are now used in many industries. With a steep angle and high acceleration, extremely low residual moisture values can be achieved in the dewatered product.

Banana screens are large, high-strokes screens, developed with the latest technology using the “thin-bed theory” to increase the efficiency in the screening of fines.

Banana screens are large, high-strokes screens, developed with the latest technology using the “thin-bed theory” to increase the efficiency in the screening of fines.

Circular motion screens are used for preliminary or final sizing of medium to coarse-grained bulk materials. The screen moves in a circular motion. Decline angles of 10 to 30 degrees can be set to give optimal throughputs for a wide range of applications.

Circular motion screens are used for preliminary or final sizing of medium to coarse-grained bulk materials. The screen moves in a circular motion. Decline angles of 10 to 30 degrees can be set to give optimal throughputs for a wide range of applications.

Linear vibrating screens are used for the highest separation efficiencies across a wide range of applications and industries. The largest screens in the world allow the highest production rates.

Linear vibrating screens are used for the highest separation efficiencies across a wide range of applications and industries. The largest screens in the world allow the highest production rates.

In the Flip-Flow screen, the elastic screen mats move like a Trampoline. The alternating cross members move relative to each other with a powerful spring mechanism, resulting in a clamping and releasing of the mats.

In the Flip-Flow screen, the elastic screen mats move like a Trampoline. The alternating cross members move relative to each other with a powerful spring mechanism, resulting in a clamping and releasing of the mats. Bed size of 4m * 3m ,Sheet Metal Cutting upto 120mm.

Bed size of 4m * 3m ,Sheet Metal Cutting upto 120mm. Bed size of 6m * 2m ,Sheet Metal Cutting upto 16mm and 42mm with Gas Cutting.

Bed size of 6m * 2m ,Sheet Metal Cutting upto 16mm and 42mm with Gas Cutting. Light Assembly Shop in Mumbai has induction heating element, light press, light machines and fixtures for assembly of motors and exciters.

Light Assembly Shop in Mumbai has induction heating element, light press, light machines and fixtures for assembly of motors and exciters. First Shed is equipped with 40 T (20/20) EOT Crane, 5T additional E.O.T. Crane and 6 nos. Jib Cranes mounted on the columns. There is also a 10T Mobile Crane, to shift the raw material from outside storage area to the Shop. Facilities available here are : Heavy Duty Shearing Machine, Heavy Duty Bending Machine, and a Shot Blasting and Painting Booth. Isolation Bays for testing Vibratory equipments.

First Shed is equipped with 40 T (20/20) EOT Crane, 5T additional E.O.T. Crane and 6 nos. Jib Cranes mounted on the columns. There is also a 10T Mobile Crane, to shift the raw material from outside storage area to the Shop. Facilities available here are : Heavy Duty Shearing Machine, Heavy Duty Bending Machine, and a Shot Blasting and Painting Booth. Isolation Bays for testing Vibratory equipments. Second Shed is equipped with 20/5 Ton EOT Crane. Facilities available here are:

Second Shed is equipped with 20/5 Ton EOT Crane. Facilities available here are: EJV has a Heavy Duty Lathe (400 mm swing diameter x 2500 mm long) along with 2 machines have been bought from Germany (a) TOS Horizontal Boring Machine with Spindle diameter 130 mm and (b) Scharmann make Horizontal Boring Machine 90 mm Spindle diameter.

EJV has a Heavy Duty Lathe (400 mm swing diameter x 2500 mm long) along with 2 machines have been bought from Germany (a) TOS Horizontal Boring Machine with Spindle diameter 130 mm and (b) Scharmann make Horizontal Boring Machine 90 mm Spindle diameter. Light Machine Shop (Vapi) has CNC Lathes, VMCs, HMCs, Grinding Machine and Key Slotting Machine.

Light Machine Shop (Vapi) has CNC Lathes, VMCs, HMCs, Grinding Machine and Key Slotting Machine. Vibration shakeout drums are generally located directly after the cast form a wet ball ejector system. From vibrations of suitable parameters with high acceleration, the separation of casting and molding sand. Unpacking the tube is at the end of the machine body is provided with a case, the use of customized grid surface, through which the used sand is discharged downwards. Unpacking pipes are suitable for castings, the outside have no fragile ribs or thin walls.

Vibration shakeout drums are generally located directly after the cast form a wet ball ejector system. From vibrations of suitable parameters with high acceleration, the separation of casting and molding sand. Unpacking the tube is at the end of the machine body is provided with a case, the use of customized grid surface, through which the used sand is discharged downwards. Unpacking pipes are suitable for castings, the outside have no fragile ribs or thin walls. Furnace Charger for feeding to furnaces in foundry & steel melting shops.

Furnace Charger for feeding to furnaces in foundry & steel melting shops. Dosing feeders are used for small applications or as hopper discharge feeders. Highly accurate control of the feed rate is possible with the electro-magnetic drive and the infinitely variable thyristor controller.

Dosing feeders are used for small applications or as hopper discharge feeders. Highly accurate control of the feed rate is possible with the electro-magnetic drive and the infinitely variable thyristor controller. Hopper discharge feeders with integral feed chutes for feeder from bunkers or hoppers are available in various designs. The FUFB deisgn uses unbalanced motors while the FRFB design has an exciter and a separate electric motor for high capacities and heavy products. Vibration amplitude of the feeder can be fixed or adjusted with a variable frequency drive.

Hopper discharge feeders with integral feed chutes for feeder from bunkers or hoppers are available in various designs. The FUFB deisgn uses unbalanced motors while the FRFB design has an exciter and a separate electric motor for high capacities and heavy products. Vibration amplitude of the feeder can be fixed or adjusted with a variable frequency drive. Mould Dump conveyors are mass-compensated low-speed resonance channels with low acceleration values. The trough is made of Wear-Resistant steel. Complex lines with curves, climbs, and switches can be realized. Low noise levels are obtained by avoiding throwing motion.

Mould Dump conveyors are mass-compensated low-speed resonance channels with low acceleration values. The trough is made of Wear-Resistant steel. Complex lines with curves, climbs, and switches can be realized. Low noise levels are obtained by avoiding throwing motion. Sorting/Casting conveyors are mass-compensated low-speed resonance channels with low acceleration values and low flow velocities. The trough is made of wear-resistant steel reinforced walls. On these machines, the casting is separated from the gate or feeder. Quiet, smooth transportation without micro throwing motion.

Sorting/Casting conveyors are mass-compensated low-speed resonance channels with low acceleration values and low flow velocities. The trough is made of wear-resistant steel reinforced walls. On these machines, the casting is separated from the gate or feeder. Quiet, smooth transportation without micro throwing motion.